Inventory Management Made Easy With Tech

Managing inventory is crucial for any business dealing with products. Be it a small neighborhood convenience store or a multinational corporation selling products worldwide, every business must keep track of its inventory. It plays a vital role in helping any business understand how its products are performing, in understanding demand, and in helping adjust supply accordingly.

The task of keeping inventory isn’t easy at all though. Let’s consider two extremes in dealing with inventory.

Scenario 1: The neighborhood convenience store

Imagine yourself to be the owner of a neighborhood convenience store and you also happen to run it. The store sells a range of food items, convenience, and consumer goods among various miscellaneous items. Naturally, you have products from different companies. For example, most stores carry at least 5 or 6 brands of cookies, and that’s just one product category. It only gets more complex from there as you have all these different product categories, each with products from a number of companies. How do you keep track of them all? How do you know how much of each you have left? How do you find out about low stock and timely order new stock? How do you figure out if somebody isn’t simply stealing from your store without a trace? How do you understand how each product is performing?

Clearly, even with a small scale of operations, there are lots of questions to be answered regarding inventory. Paper-based inventory management is usually used here, but it is extremely tedious, time-consuming, and inefficient.

Scenario 2: The multinational corporation

Consider yourself to be the supply chain manager for a global cell phone producer. You have to keep track of how many units of each type of phone offered by the company are produced at its multiple production facilities. Then you have to make sure that these are transported to the right warehouses and retailers. You have to be aware of inventory stocks, ordering new stock if it is running low, or taking measures to move inventory if it is sitting unsold for too long. There’s also the issue of making sure every unit is accounted for, to reduce pilferage in the supply chain.

How do you keep track of such a large-scale operation, spanning multiple countries and dealing with millions of units? Inventory management technology of course.

How Does Technology Make It Easier?

Technology has helped make much of this activity a lot easier. In some cases, it has even helped facilitate seemingly impossible inventory management systems.

1. Keeping Enough Inventory:

Inventory management systems keep track of individual units, based on type of product, brand, and various other features, and help figure out exactly how much inventory is in stock. Based on this figure, it also helps decide exactly how much inventory is needed to order. This makes it easier to prevent product shortages and keep just enough inventory on hand without having too much.

2. Raising Inventory Turnover:

How do you know if you’re moving inventory fast enough? Business owners need to keep a high inventory turnover ratio to ensure products aren’t spoiling, becoming obsolete or sucking up too much shelf space and working capital. Inventory management software notices patterns in sales and inventory figures, and helps determine which products are performing well and which aren’t so that you can make more profitable business decisions.

3. Planning Future Product Offerings:

By properly utilizing inventory management systems, you can better track the performance of each product and this predicts demand better. With that important insight, future product offerings are much better to plan. It helps create more solid business plans with concrete data.

4. Optimizing Storage:

If you know which products are your top sellers and what combinations of products your customers often order together, you can optimize your warehouse setup by putting those products close together and in easily accessible places. This speeds up the picking, packing, and shipping processes.

If you know which products are your top sellers and what combinations of products your customers often order together, you can optimize your warehouse setup by putting those products close together and in easily accessible places. This speeds up the picking, packing, and shipping processes.

5. Boosting Efficiency of Employees:

Training employees to use barcode scanners, RFID scanners, inventory management software and other tools necessary for electronic inventory management, helps them track inventory in a far quicker and more efficient way. It is much less tedious than manually taking it and helps employees be more satisfied with repetitive work. Moreover, since each employee can be far more efficient, you don’t even have to hire as many people as you would need with a manual system.

6. Streamlining Orders:

Inventory management software can also speed up the ordering process. You can simply scan a product barcode and type in some information to place an order and generate an invoice. You could even program your software to automatically place orders when inventory levels are too low.

7. Keeping Track of Multiple Locations:

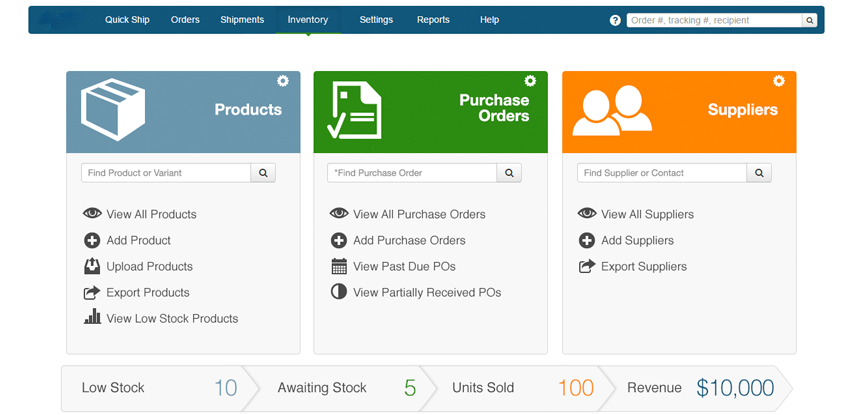

![]()

If you have multiple locations, then inventory management becomes even more important because you need to coordinate your supplies at each location depending on differences in demand and other factors. Automated inventory management systems can provide real-time data about inventory levels at every location so that you can make more informed decisions.

8. Saving Time:

Inventory management technology saves huge chunks of time. By keeping track of all the products on hand and on order, you can save yourself the hassle of manually counting inventory to make sure your records are accurate. Nor do you have to waste time repeating tedious recounts since inventory management technology does that far more quickly. Scanners and smart inventory management software do the bulk of the work.

9. Cost Cutting:

Besides saving money by reducing the amount of human labor needed, automated inventory management systems can cut costs with greater efficiency. Inventory management helps you avoid wasting money on slow-moving products so you can put it to better use in other areas of your business. It also optimizes storage and ordering to streamline the entire process.

Thus, it isn’t surprising that companies worldwide are opting for automated inventory management systems. Much of the technology needed is readily available. Just ask Softograph to revolutionize your business with smart inventory management systems, capable of automating, organizing, and giving you the edge in the competition. Even if the initial investment may seem daunting, the benefits of a well-run inventory management system can be far higher. Surely, technology can make this hectic task into a far more profitable one.